- Aerospace

-

Smart City

Smart Mobility (Rail)

Smart Mobility (Road)

-

- Marine

- Defence

- Public Security

- Digital Tech

-

Global

Cabin Interiors and Engineering Solutions

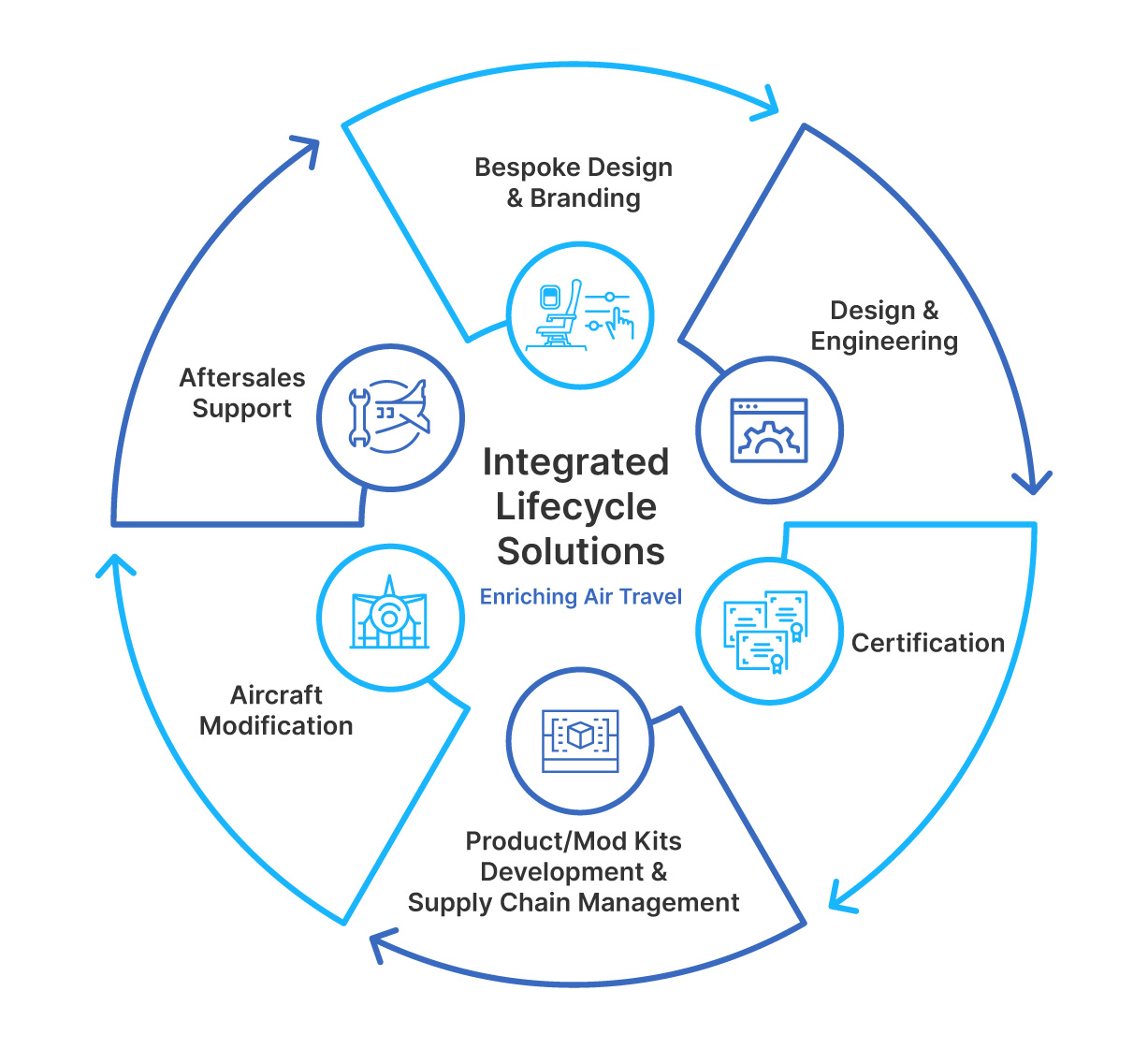

Integrated Lifecycle Solutions for Cabin Interiors

We help airlines and aircraft operators enrich and differentiate the travel experience of passengers through our integrated cabin interiors solutions. From design, engineering and product development to cabin reconfiguration and refurbishment, our solutions encompass the entire aircraft cabin lifecycle.

With over 30 years in design engineering experience and 40 Supplementary Type Certificates (STCs), we know what it takes to bring conceptual designs to fruition. Together with our global network of MRO facilities and partners, we are able to see to all your aircraft cabin interiors needs, including boutique customisation services of your cabin fittings and MRO work.

For customers with unique requirements and use cases, we have the expertise to develop customised aircraft engineering programmes starting from bespoke engineering design to certification, supply chain management, aircraft modification and aftersales support. Leveraging our breadth and depth and coupled with EASA (European Union Aviation Safety Agency) and FAA (Federal Aviation Administration) Part-21 Certification credentials, we are fully capable of producing a dedicated solution for your aircraft cabin interiors.

Our Solutions and Services

Integrated Cabin Interiors Solutions

As an aircraft cabin interiors solutions specialist with a strong record in servicing international and regional airlines, we can be your single partner for any aircraft cabin reconfiguration or interior refurbishment project.

Our integrated services span from design and engineering services, supply chain management, aircraft completion, certification and aftersales support. Contact us to learn more about refurbishing or customising your aircraft seats or cabin fittings such as aircraft galleys, lavatories and monuments.

Engineering Solutions

- Passenger to Freighter Conversion (P2F)

- Passenger to Tanker Conversion (P2T)

The world's first Boeing 757-based firefighting airtanker is the latest addition to our repertoire of aircraft conversion solutions.

The 757 Passenger-to-Tanker (P2T) solution is developed in partnership with U.S.-based Galactic Holdings LLC. This endeavour combines ST Engineering’s expertise in aircraft modifications and aviation certifications, with Galactic Holdings’ knowhow in aerial firefighting operations and certifications.

The 757P2T aptly addresses the market’s needs – its carrying capacity trumps existing Large Airtankers (LATs) while maintaining much lower runway requirements compared to the Very Large Airtankers (VLATs). The 757P2T can also respond to fires further away with its superior flying range.

Our custom-developed gravity-fed dispensing system also optimises the release of retardant/water, further enabling effective and efficient firefighting performances.

The 757P2T not only extends the service lives of passenger jets, but also empowers the global fight against wildfires, further enhancing our push for sustainability and care for the environment.

Specifications:

Retardant/water capacity: >6,000gal (27ton / 60,000lbs / 23,000ℓ)

757 Platform range: 7,200km (3,900nm / 4500mi)

The World's First Certified Expandable Lavatory - ACCESS

ACCESS is our proprietary aircraft lavatory with a unique feature for expandable space that is specially designed to provide a dignified and pleasant air travel experience for aircraft passengers with reduced mobility (PRMs). Made for narrow body aircraft where space is a constraint, the lavatory, through the use of a moving wall, can be expanded to provide 40% additional space compared to a conventional lavatory. The expanded lavatory is large enough to allow a passenger in a wheelchair and an attendant, if needed, to enter and use the facilities with comfort and privacy.

The patented design will provide the additional 40% of volume without altering the cabin layout or reduce seating capacity and galley space. It allows airlines to create an inclusive air travel experience for PRMs while maintaining their business models. The ACCESS expandable lavatory leverages existing structural attachment points, electrical and system connections to minimise the retrofit cost for airlines.

In addition to the expandable feature, ACCESS also includes features such as an infrared sensor toilet flush, floor-to-ceiling strip lighting, anti-microbial work surfaces, anti-slip flooring and a range of grab bars for a stylish, relaxing yet practical space that enhances customer experience. Find out more.

Interior Part Manufacturing, Refurbishment and Part Manufacturer Approval Capabilities

With our in-house aircraft engineering capabilities, we are able to refurbish, restore and recertify your used aircraft parts - passenger service units, windscreens, class partitions and stowage bins - to mint condition. Through our EASA Part 21 DOA certification, we can produce 3D printed PMA aerospace parts to help improve your aircraft availability and turnaround times.

Integrated Cabin Interiors Solutions

As an aircraft cabin interiors solutions specialist with a strong record in servicing international and regional airlines, we can be your single partner for any aircraft cabin reconfiguration or interior refurbishment project.

Our integrated services span from design and engineering services, supply chain management, aircraft completion, certification and aftersales support. Contact us to learn more about refurbishing or customising your aircraft seats or cabin fittings such as aircraft galleys, lavatories and monuments.

Engineering Solutions

- Passenger to Freighter Conversion (P2F)

- Passenger to Tanker Conversion (P2T)

The world's first Boeing 757-based firefighting airtanker is the latest addition to our repertoire of aircraft conversion solutions.

The 757 Passenger-to-Tanker (P2T) solution is developed in partnership with U.S.-based Galactic Holdings LLC. This endeavour combines ST Engineering’s expertise in aircraft modifications and aviation certifications, with Galactic Holdings’ knowhow in aerial firefighting operations and certifications.

The 757P2T aptly addresses the market’s needs – its carrying capacity trumps existing Large Airtankers (LATs) while maintaining much lower runway requirements compared to the Very Large Airtankers (VLATs). The 757P2T can also respond to fires further away with its superior flying range.

Our custom-developed gravity-fed dispensing system also optimises the release of retardant/water, further enabling effective and efficient firefighting performances.

The 757P2T not only extends the service lives of passenger jets, but also empowers the global fight against wildfires, further enhancing our push for sustainability and care for the environment.

Specifications:

Retardant/water capacity: >6,000gal (27ton / 60,000lbs / 23,000ℓ)

757 Platform range: 7,200km (3,900nm / 4500mi)

The World's First Certified Expandable Lavatory - ACCESS

ACCESS is our proprietary aircraft lavatory with a unique feature for expandable space that is specially designed to provide a dignified and pleasant air travel experience for aircraft passengers with reduced mobility (PRMs). Made for narrow body aircraft where space is a constraint, the lavatory, through the use of a moving wall, can be expanded to provide 40% additional space compared to a conventional lavatory. The expanded lavatory is large enough to allow a passenger in a wheelchair and an attendant, if needed, to enter and use the facilities with comfort and privacy.

The patented design will provide the additional 40% of volume without altering the cabin layout or reduce seating capacity and galley space. It allows airlines to create an inclusive air travel experience for PRMs while maintaining their business models. The ACCESS expandable lavatory leverages existing structural attachment points, electrical and system connections to minimise the retrofit cost for airlines.

In addition to the expandable feature, ACCESS also includes features such as an infrared sensor toilet flush, floor-to-ceiling strip lighting, anti-microbial work surfaces, anti-slip flooring and a range of grab bars for a stylish, relaxing yet practical space that enhances customer experience. Find out more.

Interior Part Manufacturing, Refurbishment and Part Manufacturer Approval Capabilities

With our in-house aircraft engineering capabilities, we are able to refurbish, restore and recertify your used aircraft parts - passenger service units, windscreens, class partitions and stowage bins - to mint condition. Through our EASA Part 21 DOA certification, we can produce 3D printed PMA aerospace parts to help improve your aircraft availability and turnaround times.