What's next for the maritime industry? As companies look to digital transformation and seek streamlined solutions to optimise efficiencies and reap cost savings, ST Engineering has designed and developed its very own ship management system to address the gap in availability of such solutions.

Digital transformation for the maritime industry remains a key opportunity for many companies to enhance operational efficiencies, increase productivity and stay ahead of competition. Ship owners and operators are constantly seeking streamlined solutions, energise their business with innovative technologies to overcome challenges and reap cost savings as a result.

To address the gap in availability of such solutions, ST Engineering has started to design and develop its very own ship management system. Since 2012, ST Engineering has used data analytics and machine learning to narrow down areas to service and repair in vessels before it breaks down. Efforts have resulted in the NERVA Ship Management System and Sensemaking System (SMS2), which integrates predictive maintenance into the ship management system (SMS) developed by ST Engineering, NERVA SMS.

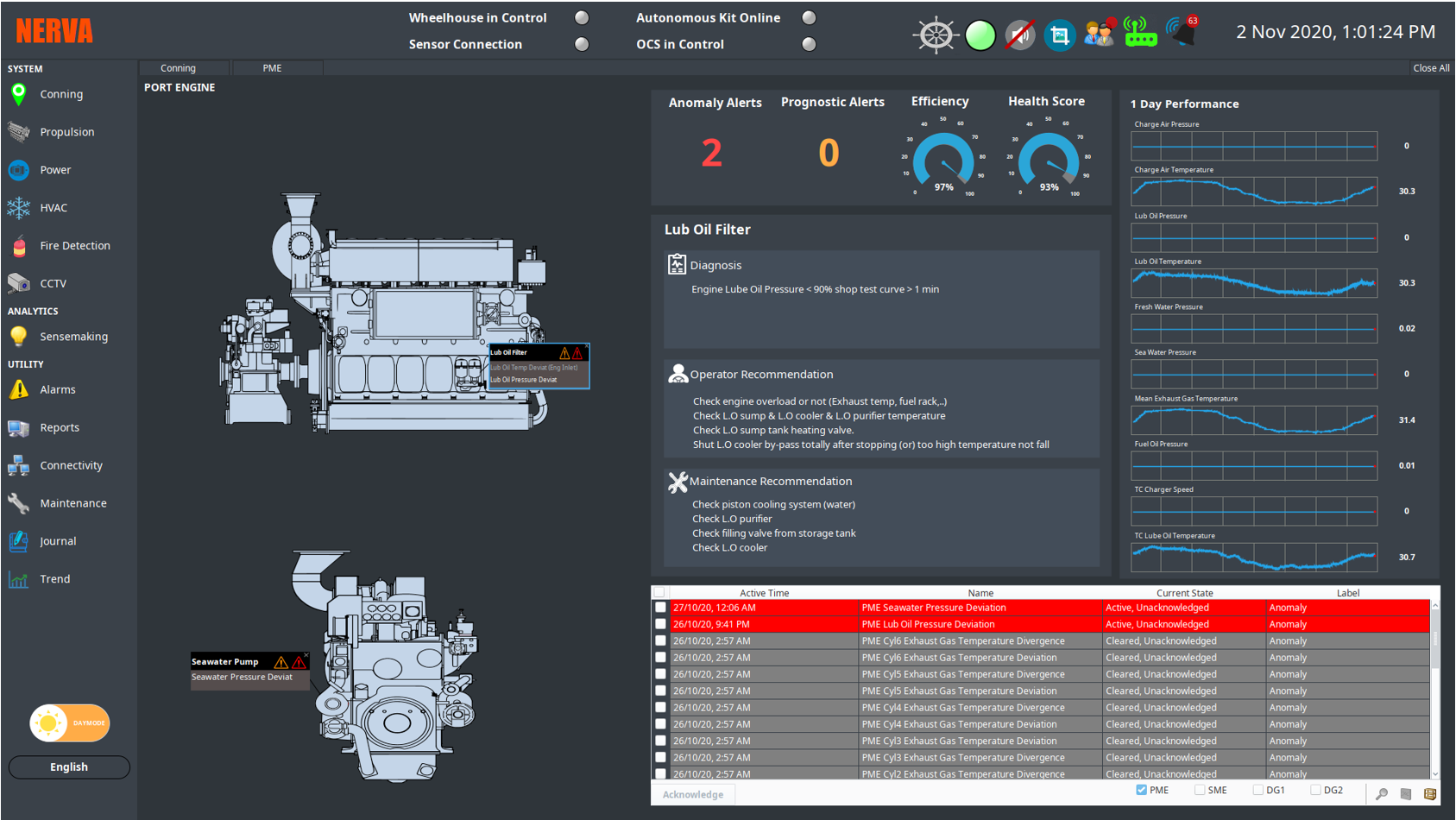

The NERVA SMS allows centralised control and monitoring of platform sensors and systems from a remote location. By providing ship operators with real time, on-board and remote access, it guarantees secure and efficient operations across a variety of vessels.

Designed to meet the requirements of the International Maritime Organisation and major classification societies, the ship management system uses reliable marine-graded and type-approved Commercial-Off-The-Shelf products. This system has been deployed on various platforms and projects, including newbuild and retrofit projects.

The capabilities of the NERVA SMS is enhanced with its Sensemaking module, forming NERVA SMS2. Effectively incorporating data analytics and machine learning technologies, NERVA SMS2 reduces unplanned downtime through predictive diagnostics and greatly enhances operational efficiencies by changing the nature of maintenance from reactive to predictive.

NERVA SMS2 also prolongs the maintenance intervals with the implementation of condition-based monitoring. Maintenance is done on a need-to basis instead of a fixed maintenance schedule that may not entirely utilise the lifecycle of various component parts. This improves uptime and extends the lifespan of equipment, hence generating cost-savings. Also equipped with self-learning capabilities and decision support engine, the system constantly analyses and refines its predictors for improved accuracy, while providing advisories and recommended preventive actions to the operator.

The capabilities of NERVA SMS2 has been expanded to include Smart Water Management Systems. It works as a centralised control and monitoring system for efficient management of water processes by connecting with different sensors and processes instruments, customised for plant operations.

Integrating technological advancements in process automation with shipbuilding expertise, NERVA SMS2 offers state-of-the-art ship and water management solutions that are customisable for most vessels and plant types. Ship owners and plant owners are now empowered with full flexibility to customise the user-friendly and intuitive Human-Machine Interface to meet their specific needs, no matter how complex their needs may be.

Copyright © 2025 ST Engineering

By subscribing to the mailing list, you confirm that you have read and agree with the Terms of Use and Personal Data Policy.