The aerospace sector is transforming. As manufacturers face unprecedented production rates for next-generation aircraft, supply chains are being stretched, traditional manufacturing methods are being tested and pressure is mounting to deliver parts faster without compromising quality, cost or sustainability.

This challenge is especially pronounced in the production of complex aerostructures and composite tooling. Once lengthy and linear processes, these workflows now face flexibility, scalability and near-immediate responsiveness demands. As suppliers grapple with long lead times, skill shortages and supplier fragility, ST Engineering is actively reshaping the traditional manufacturing model by harnessing innovation and technology to enhance productivity and efficiency.

With its Quick Turn Tooling capability, built on in-house additive manufacturing and digital integration, our engine nacelle design and manufacturing facility ST Engineering MRAS (MRAS) offers a faster, more resilient and more sustainable path to composite tooling.

Historically, aerospace tooling development has relied on Computer Numerical Control (CNC)-machined metal or composite moulds. These conventional methods require extensive planning, expert programming and skilled operation. Each step adds time, cost and potential delay.

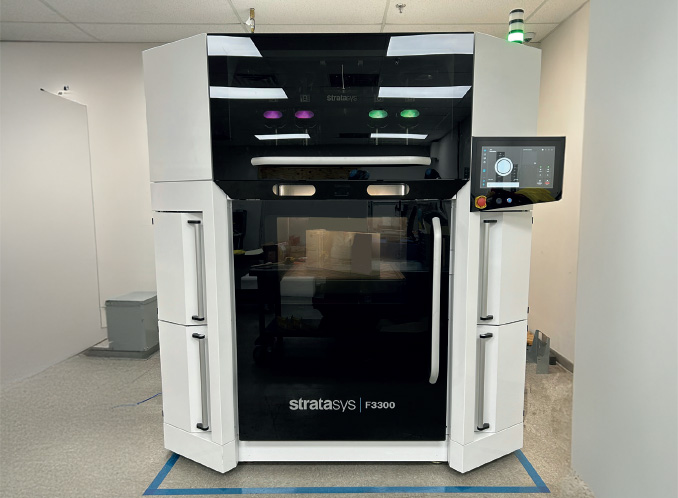

MRAS replaced this linear and resource-heavy process with a faster and more flexible alternative using Fused Deposition Modelling (FDM). This additive manufacturing method constructs tooling layer by layer using thermoplastic materials, eliminating the need for complex setups or outsourcing.

The benefits are immediate. FDM tools can be produced at a fraction of the time and at around 25% lower cost compared to traditional counterparts. If a revision is needed, a new tool can be printed quickly and inexpensively without affecting the overall schedule.

A key enabler of this speed is MRAS’ integrated digital workflow, which harmonises design, simulation and manufacturing in a single data stream. Instead of having to wait for tooling teams or suppliers, its engineers can design and print tooling directly, compressing the development lifecycle into weeks or even days for certain applications. Tooling and manufacturing development begins as soon as the conceptual designs are completed.

This digital integration allows MRAS to reduce its dependence on specialised machinists and programmers by lowering the technical barrier to tooling development. A result of that is it can refocus skills training efforts toward cross-functional training and digital upskilling, helping its workforce adapt and respond quickly to evolving programme needs.

As aircraft production accelerates to meet rising flying demand, manufacturing systems must evolve to keep pace while reducing environmental impact. MRAS’ Quick Turn Tooling addresses both challenges by combining scalability with sustainability. The approach leverages rapid prototyping and reusable high-quality masters, enabling OEMs and major suppliers to accelerate the path from concept to full-rate production.

At the same time, the use of additive manufacturing significantly reduces material waste, energy consumption and retooling costs, offering a leaner and greener alternative to traditional subtractive methods. By embedding both speed and efficiency into composite tooling, MRAS delivers a solution that supports the industry’s drive for higher output and a lower carbon footprint.

Composite tooling itself is well established in aerospace — but we are redefining what it means to access and scale that tooling. With Quick Turn Tooling, we move beyond providing a service to creating a new model for how aerospace manufacturing can operate: faster, smarter and more resilient.

By internalising key tooling operations and deploying wholly owned 3D printing capabilities, we reduce external dependencies and build supply confidence into our processes. This ensures not only speed and reliability, but also the flexibility to adapt as programmes evolve. It is a forward-looking blueprint that aligns with the aerospace sector’s dual goals of meeting rising demand and achieving more sustainable, efficient manufacturing.

Copyright © 2026 ST Engineering

By subscribing to the mailing list, you confirm that you have read and agree with the Terms of Use and Personal Data Policy.